Reference

Fraunhofer-inHaus-Zentrum

Heat/cold consumers

- Concrete core activation

- Ventilation

Cold generator

- Free cooling

- Chiller

Planning

- Ing. Büro Jansen

Execution

- Josef Rehms GmbH

Massive pump power savings

The ongoing hydraulic faults in the research and development activities in the field of intelligent room and building systems at the Fraunhofer-inHaus-Center in Duisburg were the reason for converting the hydraulic system to Zortström. The Fraunhofer-inHaus-Center Duisburg confirms massive pump power savings and optimally functioning hydraulics in contrast to the classic solution.

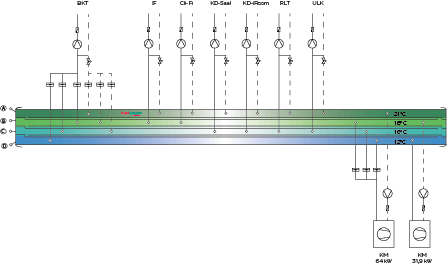

The solution: four variable temperature levels

The existing solution was replaced by a Zortström center with 4 variable temperature levels. This made it possible to decouple the water volumes and eliminate the hydraulic faults. The tests planned at the institute could then be carried out without any problems.

Test consumers that originally required more cooling can now be supplied with cooling as required. At the same time, the pump power requirement was reduced by approx. 70 – 85%. All cooling circuits, all connections from diameter DN100 to DN25, function simultaneously without any mutual hydraulic interference.

Initial situation and objectives

The aim of the system is to carry out the tests smoothly and evenly according to test specifications, which was not possible due to the originally strong mutual influence on the hydraulic system. As those responsible confirmed, no tests could be carried out due to the suction behavior that resulted from the originally strong mutual hydraulic influence on the traditional system. The most powerful consumer circuit pump even drew water in the smallest consumer group against the direction of flow via the return.

Decoupling the water flows

After the conversion, the Zortström acts as a hydraulic zero point and decouples all water flows. The consumer circuits are now operated as required and the generators supply cooling to the Zortström at precisely the required target temperatures. All devices/consumer groups connected for the tests can now be easily tested and evaluated.

The pump power savings achieved are also documented in the multi-page results report of a study commissioned by Zortea.

The additional control valves installed for research purposes now allow the circuits to be operated at different temperatures. This allows the effects of temperature differences and permitted humidity, such as with concrete core activation, various wall and ceiling structures and much more to be researched. The tasks relating to building research at the Fraunhofer-inHaus-Center Duisburg are very extensive and range from quality assurance to energy saving using state-of-the-art electronics.

Benefit

Efficient

- Increased efficiency (COP) thanks to precise temperature separation.

- Best possible capacity control of the chillers depending on the temperatures in the Zortström.

- Tests with all control options can be carried out without any problems.

- Speed-regulated high-efficiency pumps run with minimal power consumption and do not rock each other.

- Overall quiet system behavior.

Simple

- Uncomplicated, clear hydraulics despite and even in the most varied load and operating conditions.

Safe

- The required temperatures are precisely available in the Zortström at all times.

- Transparent control increases operational safety.