Reference

Bodensee-Therme Konstanz

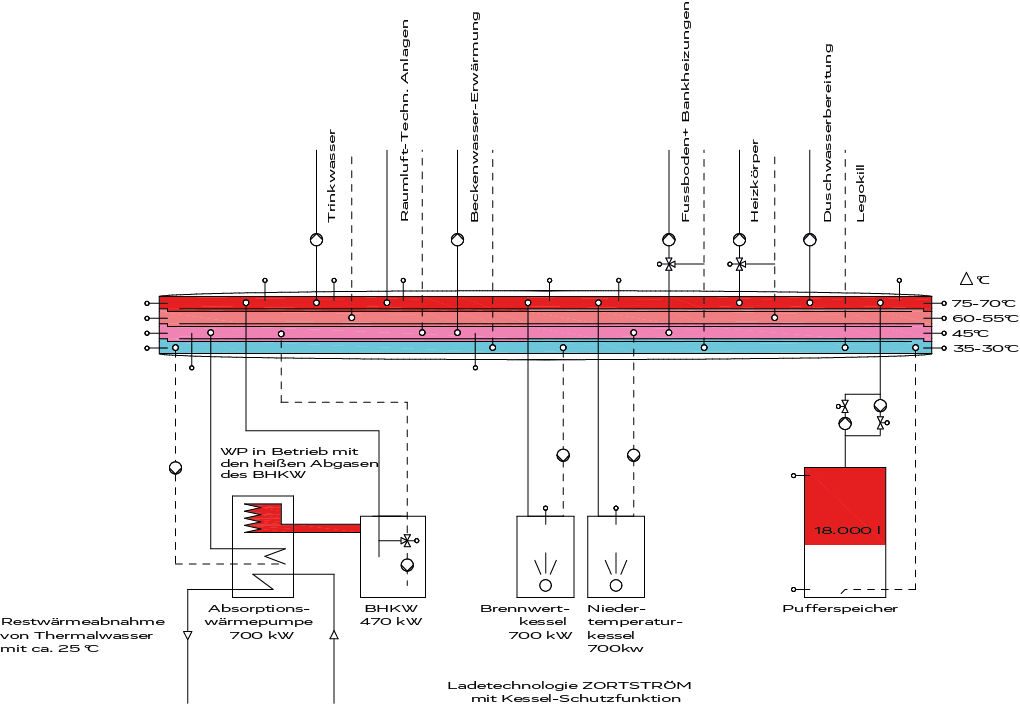

Heat generator

- Combined heat and power unit CHP

- Condensing boiler / gas boiler

- Heat pump

Heat/cold consumers

- Underfloor heating

- Radiators / static heating

- Ventilation

Cold generator

- Absorption chillers

Planning

- Greiner Engineering

Execution

- Imtech Deutschland GmbH & Co. KG

Wellness oasis on Lake Constance

In Constance, directly on Lake Constance, where the “Jaköbilibad” used to be, a fantastic wellness oasis with thermal baths, sauna landscape and an attractive outdoor pool area has been created with a great deal of architectural sophistication and all the means of art. Generously embedded in the gently sloping terrain, the Bodensee-Therme offers a wonderful view of the lake and, on a clear day, of the Swiss mountains.

Almost 3,000 m² of thermal water are available to guests both inside and out. Nine pools with water temperatures ranging from 26° to 37°C make the visit an experience for all the senses. A central concern in the planning was an economical, user-friendly and perfectly functioning energy concept. The city of Constance relied on existing and alternative energy sources and the Zortström, which connects everything.

Innovative energy concept

Under the direction of DI Hägele from the Constance public utility company, an extremely innovative energy concept was developed in collaboration with the Bavarian Center for Applied Energy Research. It uses existing and alternative energy sources and makes the Bodensee-Therme-Konstanz a showpiece from an ecological point of view.

Water at a temperature of 29.6 °C is tapped from the “Hörnle” thermal spring 660 m away and fed into the facility. A newly designed absorption heat pump heats the swimming pool water as well as the floor, wall and bench heating to the desired temperatures. In addition to heating the building, an additional combined heat and power unit increases the water temperatures for the boiler and showers and guarantees legionella protection.

Two gas boilers are also used for safety reasons. This unique concept makes it possible to operate the absorption heat pump with the exhaust gases from the combined heat and power unit. The two appliances are ideally matched to each other. No other energy is therefore required to operate the heat pump – Zortström connects.

Maximum efficiency with minimum power consumption

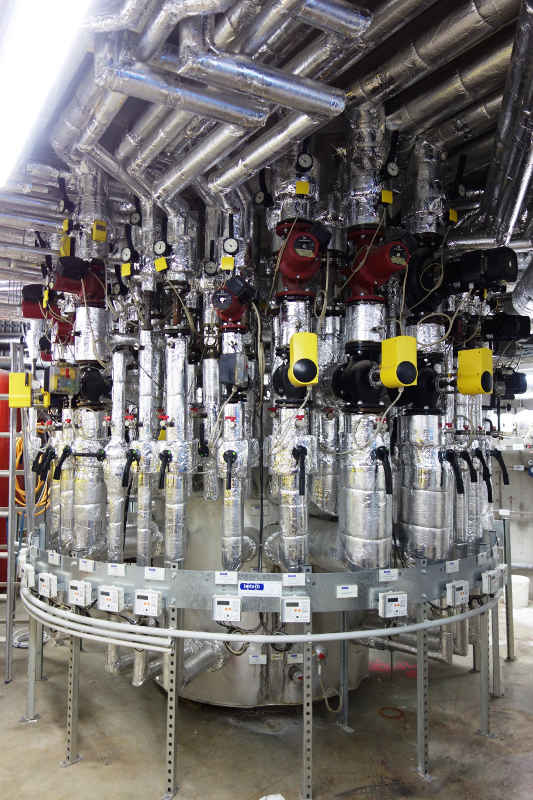

The system is highly efficient. This is because the agile and flexible Zortström technology ensures the trouble-free collection and distribution of energy flows in several temperature stages. In this case, this means that the individual heat consumers are supplied with the right temperatures via 31 connected system circuits without the water flows interfering with each other. And thanks to the use of smaller pumps, electricity consumption is reduced to a minimum. The sophisticated Zortström technology ensures maximum utilization of the available energy.

For installation reasons, the hot water supply for pumps and valves has been moved to the bottom. Thanks to the FlowSplit temperature separation, a reverse installation is perfectly possible.

Benefit

Efficient

- Optimum running time of the CHP unit and the boiler.

- High-efficiency pumps run with minimal power consumption and don't rock each other.

Simple

- Uncomplicated, clear hydraulics despite a wide variety of load and operating conditions.

- Simple integration of the combined heat and power unit and the gas boiler into the absorption chiller.

Safe

- The required temperatures are precisely available in the Zortström at all times.

- Transparent control increases operational safety.