Reference

Festo AG & Co. KG / Technolgiefabrik

Heat generator

- Biomass

Planning

- Zortea Gebäudetechnik GmbH

Execution

- Büttner Haustechnik GmbH

One of the first local heating supply systems in Bavaria

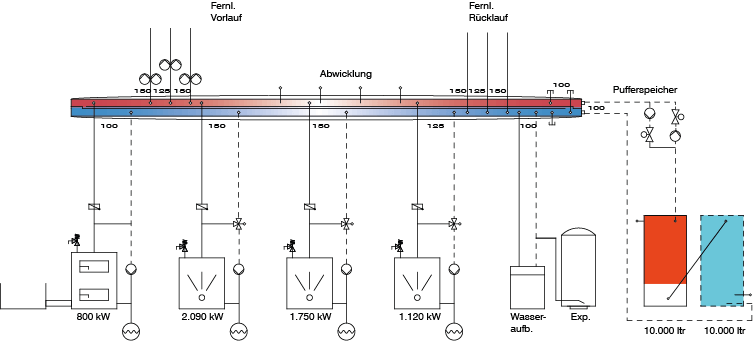

A local heating supply system, built in 1977 and thus one of the first in Bavaria, served more than 420 residential units via three long-distance pipelines. These were or are divided into multi-storey residential units and single-family houses. Measured against the outside temperature, the residential units were supplied with three speed-controlled pumps in the district heating groups.

Cost optimization as the primary goal

Three oil boilers with a combined output of 5.3 MW served as the heat source. However, the massive price increases for heating oil and serious malfunctions in the hydraulics forced the system to be modernized. Due to the unfavorable “piping” in the central heating system, the heating pumps obstructed each other so much that they partially slowed down the heating water flows against each other. The resulting energy consumption was enormous – and cost reduction was the top priority in the renovation project. While the wood chip boiler covers the base load, the oil boilers are controlled according to the additional heat demand. The positive result so far – a boiler only had to be switched on occasionally.

Zortström technology at the heart of the system

The capacity of the originally installed local heating pipes of 180 m² of water made a 20,000 liter buffer tank unnecessary for the time being. However, it can be retrofitted at any time. In general, nothing stands in the way of expansion (e.g. via a CHP unit). The Zortström technology at the heart of the system ensures that the heat layer in the storage tank rises and falls smoothly. Possible peak consumption times can thus be taken into account immediately and the central heating system is in balanced operation.

Benefit

Efficient

- Effective output control of the boilers depending on the temperatures in the Zortström and in the buffer.

- High-efficiency pumps run with minimal power consumption and don't rock each other.

- Significantly reduced power consumption of the circulation pumps.

Simple

- Uncomplicated, clear hydraulics despite a wide variety of load and operating conditions.

- Simple buffer management for the biomass boiler via the Zortström.

Safe

- The required temperatures are precisely available in the Zortström at all times.

- The Zortström with direct connection to the consumer circuits is the first to be supplied by the boilers. This creates operational reliability.